Tell us your job

First up we’ll need to know some details about your job. How detailed is it? What size and materials do you require? How many do you need?

We'll give you a quote

A member of our team will contact you (usually the same day) to discuss requirements in more detail and will then give you a quote for the job.

We'll create your order

Our skill is interpreting your design, and using our combination of CNC machinery and skill to turn your ideas into a finished quality product.

How does laser engraving work

Laser Engraving (or Laser Etching) is a surface technology. The laser interacts with different types of material in different ways:

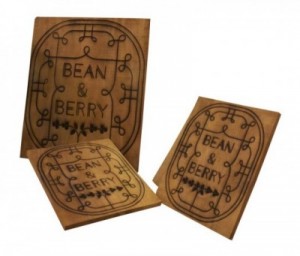

For Organic Materials such as Wood the laser burns the surface of the material, almost like a very accurate branding iron. The depth can be varied and 3D effects can be created.

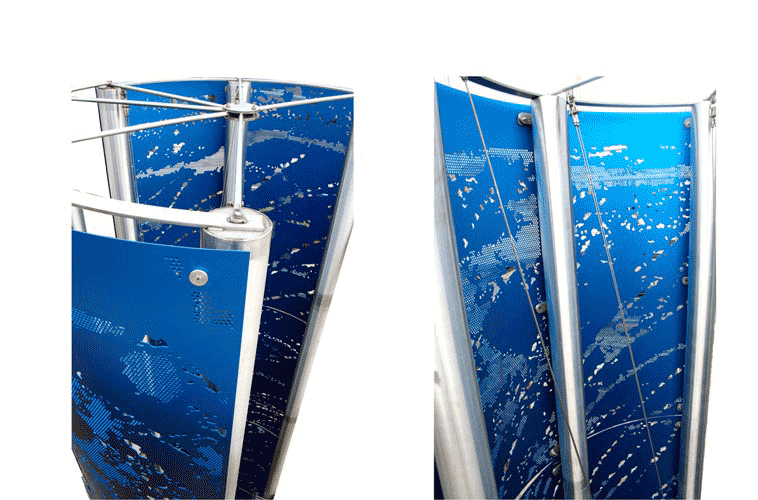

For Polymers such as Acrylic the laser vapourises part of the surface, changing its appearance. 3D effects can be created, but not as successfully as with Organic Materials.

For Metals the normal method of marking is to use a YaG laser to alter the structure of the material surface. Coated metals are different – for example with painted brass we remove the paint, with anodised aluminium we change the colour of the anodised surface.

For Natural Materials such as Granite and Stone the laser actually causes tiny fractures in the surface, and this results in a textural and contrast difference with the surrounding material. We can only do 2D engraving with these materials.

Laser Engraving can work in two different ways – we can Raster Engrave or Vector Engrave.

Raster Engraving uses a raster-based image such as a JPG and the laser treats this as one big piece of Art. To recreate this image the laser scans back and forth over the material and fires the power proportionate to the depth of greyscale in the image – black areas receive maximum laser power, white areas do not get engraved, the shades between the two get a varying amount of laser power. This allows us to create photographic images and 3D effects up to a resolution of around 1000dpi. Raster Engraving is possible up to a maximum size of 960 x 610mm.

Vector Engraving is very different – it uses a vector-based file such as an Illustrator or Autocad file and the laser in effect follows the lines. The laser power is not variable, it switches on at the start of the line and switches off at the end therefore there is no varying the depth or the effect. The only difference between Vector Laser Engraving and Laser Cutting is power – if we set the laser power too high when engraving we’ll cut the material; if we set the power too low when cutting we’ll engrave! We can Vector Engrave up to 960 x 610mm work area.

WHAT MAKES LASER ENGRAVING SO POPULAR?

- The level of detail achievable is very high

- Laser Etching is a non-contact process meaning fragile materials can be processed

- Photographic images can be engraved onto many materials

- Lasers are capable of etching 3D images in many materials

- Virtually any type of image can be used to produce the engraved part

- Laser Engraving is very cost effective

Technology

We use the very latest laser cutting and laser engraving machines

Top Quality

Nothing leaves our production line unless it’s absolutely perfect

Bespoke

We work with you to make your ideas become reality

On Budget

If we give you a price, we’ll stick to it, with no hidden extras

On Time

Client deadline looming? Just let us know and we’ll do our best for you