Tell us your job

First up we’ll need to know some details about your job. How detailed is it? What size and materials do you require? How many do you need?

We'll give you a quote

A member of our team will contact you (usually the same day) to discuss requirements in more detail and will then give you a quote for the job.

We'll create your order

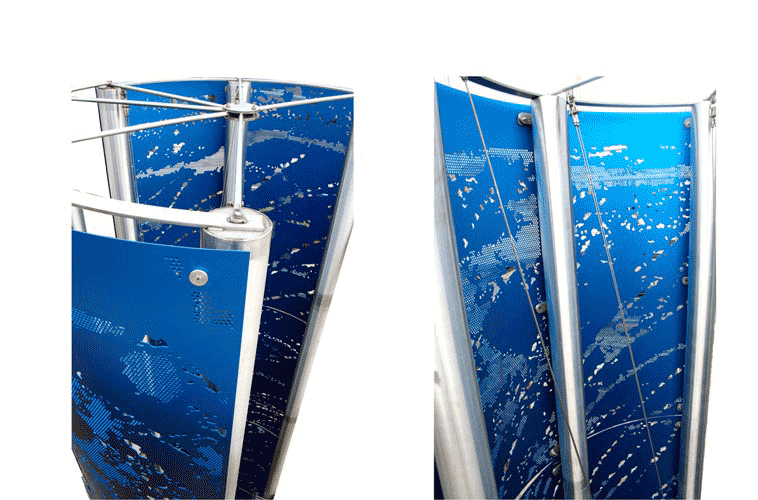

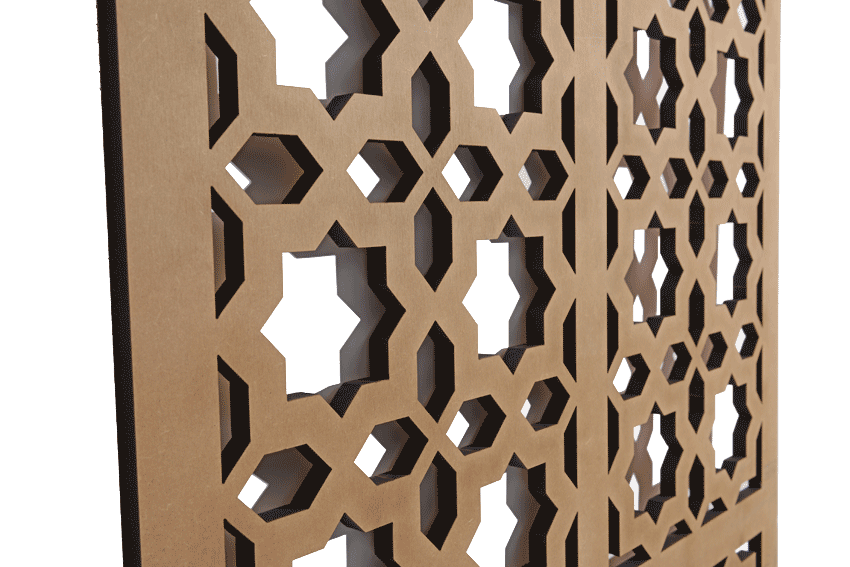

Our skill is interpreting your design, and using our combination of CNC machinery and skill to turn your ideas into a finished quality product.

How does laser cutting work

Laser cutting works by melting, burning or vapourising the material, while an assist gas is employed to “clear” the cut zone of the molten / burnt material or the gas vapour. In the early days of laser cutting the setting of the laser to produce the desired effect was very much a manual process and very complex. The latest machines now come with many of the common parameters pre-programmed, allowing much easier setting. However operators still require many hours of training to run a laser safely, efficiently and economically.

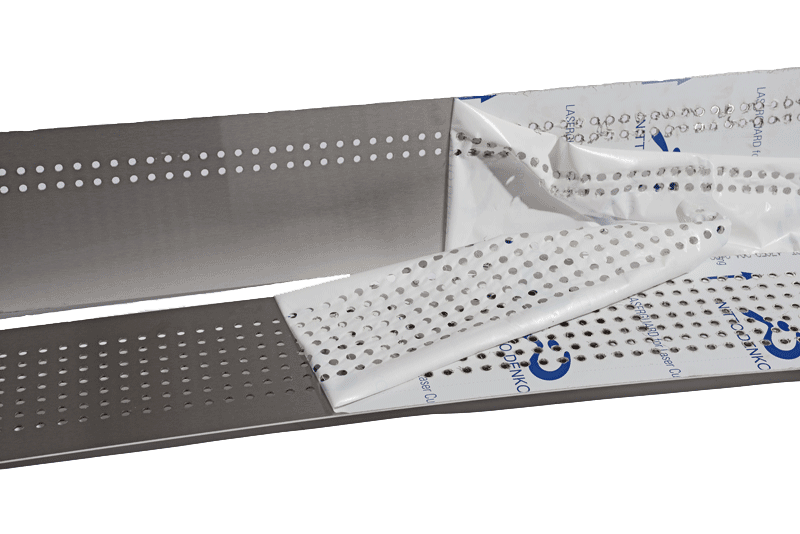

Laser cutting is a technology that has been used in industry since the 1970’s. The first common application was for sign-making, mainly cutting acrylic. Since then the process has been adopted and adapted by virtually every industry group, and is now a significant process in every manufacturing economy. Laser cutting is excellent at processing many different materials. Unlike physical machining laser profiling is not affected by the hardness of a material, meaning materials such as high carbon steels can be cut as easily as standard mild steel.

The cutting process is very complex, but basically involves pre-piercing the material outside the area of desired cut, moving the laser beam into the cutting area to apply heat, and finally use an assist gas to remove the heated material and produce the cut. The type of assist gas employed is critical, and is dependent on the material to be laser cut; most commonly used are Oxygen (used predominantly for carbon steels), Nitrogen (used for non-ferrous steels & non-metals) and Argon (used for more exotic materials such as titanium).

What makes laser cutting so popular?

- High level of accuracy

- High level of detail

- Repeatiblity and consistency

- Wide range of materials can be cut

- Speed of process

- Low cost of parts

Technology

We use the very latest laser cutting and laser engraving machines

Top Quality

Nothing leaves our production line unless it’s absolutely perfect

Bespoke

We work with you to make your ideas become reality

On Budget

If we give you a price, we’ll stick to it, with no hidden extras

On Time

Client deadline looming? Just let us know and we’ll do our best for you